A brief return to the time when the work you did...was Done Well!

"When I started this business over 15 years ago, my goal was to provide the highest level of innovation, workmanship and craftsmanship magnified by an obsession to customer care and attention......that tradition continues."

Allan Gendelman

What makes Done Well unique?

01.

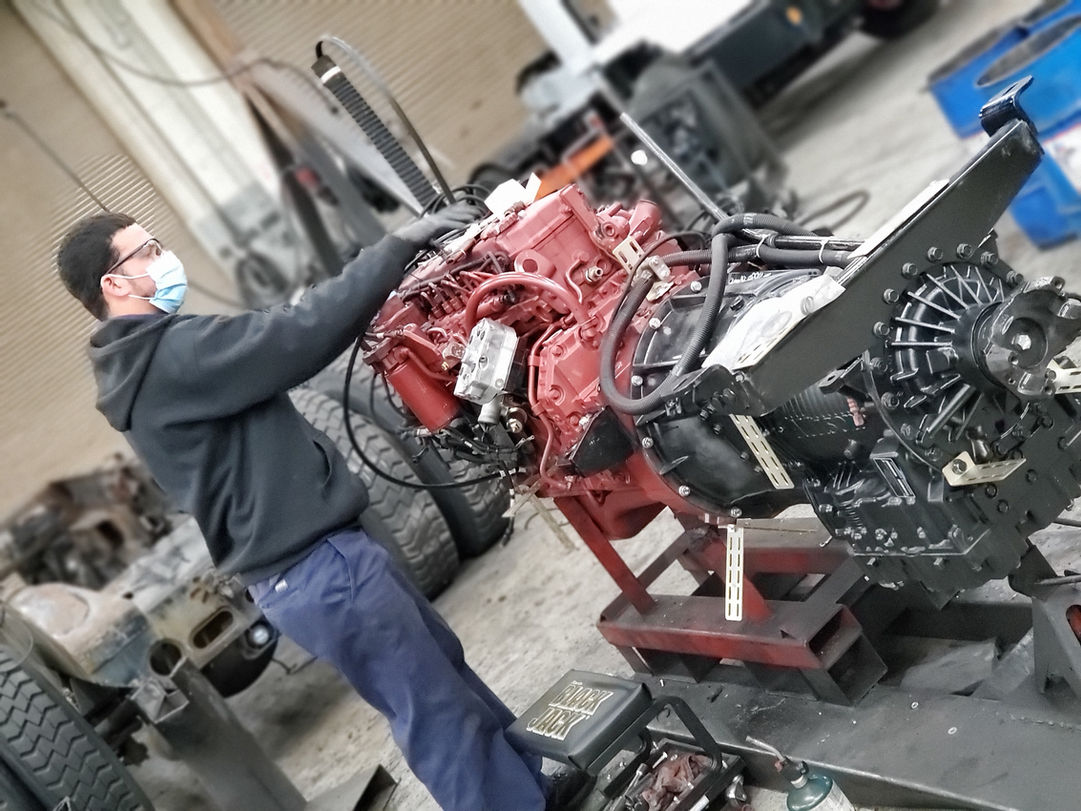

Custom Metal Fabrication

We are experts in adaptable, precision fabrication—from sheet-metal fabrication and plasma CNC machining. We bring you innovative new ways to increase efficiency, reduce cost, and improve performance with agility

02.

Custom PM Device and App

We designed and developed our patent pending ITTP tester which revolutionizes PM. By connecting the ITTP you are able to perform various PM compliance tests from any IOS device within minutes. While the ITTP is an integral part of the PM service we offer our clients, the ITTP allows you to test your tractors 24/7/365 onsite or on the road.

03.

Custom Lift Systems

Our Custom Electric over Hydraulic Lift System with easy access pull out tray is solar powered and can lift any trailer to dock height.

04.

Custom Sweeper Magnets

Our custom sweeper magnets greatly reduce the possibility of costly and dangerous flat tires and injuries caused by nails, scrap iron particles, welding remnants, wire, staples, tacks, and metal shavings. Simply hang a magnetic sweeper from your forklift or vehicle bumper and "sweep" all contaminated areas.

05.

The brands we work with....

Due to the fact that we have the resources, knowledge and experience in building custom solutions for our customers, that ability and agility is what allow us to know exactly how to repair and fix any issue. The same engineers that design, render and cut all pieces for our custom builds are the same ones that do the same thing for any repair. A trailer needs a certain piece....we can simply make it, reducing lead times, and creating asset uptime.

Our Services

-

60 x 14 Down Draft Paint Booth

-

Collision Repairs

-

Complete PM's

-

Liftgates & Hoists

-

Lights

-

Panel Repair, Patches & Replacements

-

Pintle Hooks & Couplers

-

Roof Repair, Patches & Replacements

-

Sand Blasting

-

Suspensions

-

Trailer Brakes

-

Upper Coupler Replacement

Fleet Services

-

Mobile on-site PMs

-

FHWA Inspections

-

On-site Repairs

-

Safety items handled on-site

-

Cost tracking and budgeting

-

Emergency roadside service

-

Trailer and DOT inspections

-

Brakes and airlines

-

Axles

-

Suspensions

-

Kingpin

-

and much more

-

Why Done Well Trailer & Body?

If you have discovered Done Well Trailer & Body, you have likely seen the wide array of trailer repair shops available. While all can offer repair work and certain template fabrication, Done Well is the only one who has the experience and personnel to take any custom concept or repair need and design, fabricate, weld, build and paint the solution all in house.

Done Well has been able to successfully fuse cutting edge technology, equipment and craftsmanship. Bring your toughest need or wildest idea to either of our locations in Paterson, NJ or Syracuse, NY and see us work,

Have a custom need, we have you covered

All custom fabrications occur at our flagship location in Paterson, NJ and follow the below general process:

-

The process begins with a request consultation and review where specifications are discussed, measured and documented

-

Our in-house engineer then designs and creates a CAD drawing and 3D drawings based on the customer's specifications

-

A CAD rendering is then delivered to our fabrication room where each and every piece for the request is precisely cut by our automated plasma cutting machine

-

All processed pieces are then bend, fitted, welded, fastened, bolted and wired depending on the CAD rendering

-

Finally, the finished product is then moved into our paint booth to receive a fresh coat of paint to specification.